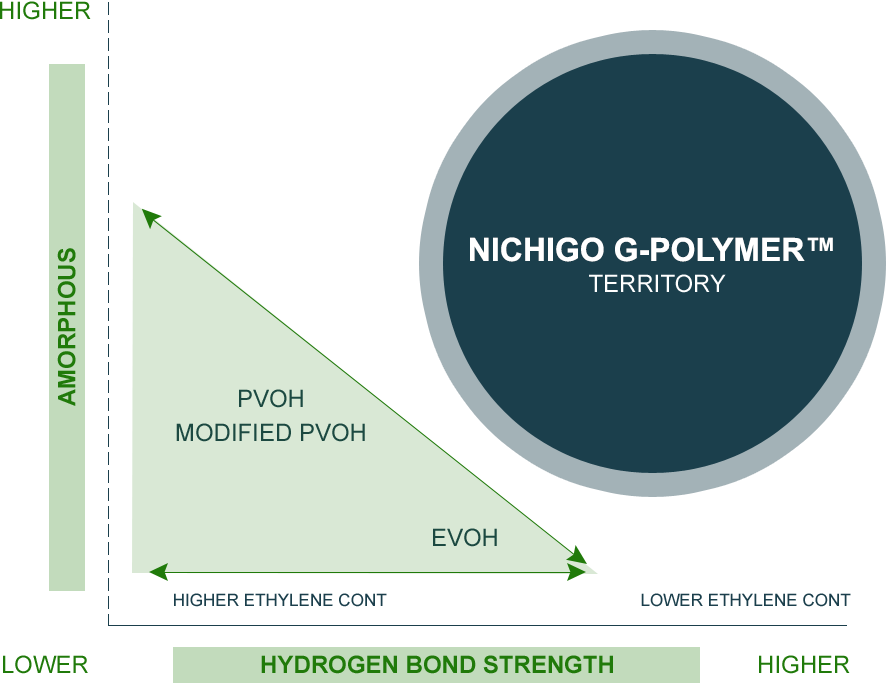

Based on these unique characteristics Nichigo G-Polymer™ has the following fundamental properties.

Design

General Grades

Powder Type

| Type | Grade | Viscosity *1 (mPa.s) | Estimated Polymerization Degree | Saponification Degree (mol%) | Melting Point *2 (Degree C) |

|---|---|---|---|---|---|

| Fully Hydrolysed | AZF8035W | 3.0 | 300 | Min98.0 | 172 |

| AZF8035Q*3 | 3.0 | 300 | Min98.0 | 172 | |

| OKS-1011 | 3.0 | 300 | Min98.0 | 206 | |

| OKS-8118*3 | 3.0 | 300 | Min99.0 | 224 | |

| OKS-8077 | 3.3 | 330 | Min99.0 | 190 | |

| BVE8049Q*3 | 4.5 | 450 | Min99.0 | 190 | |

| OKS-1009 | 15.0 | 1,200 | Min99.0 | 190 | |

| Partially Hydrolysed | OKS-8096 | 4.5 | 450 | 93.0 | 168 |

| AYB8041W | 3.0 | 300 | 89.0 | 180 | |

| OKS-8089 | 4.0 | 450 | 86.0 | 159 |

*1: Viscosity of 4% aqueous solution at 20 deg C

*2: Measured with DSC, both heating and cooling speeds of 10 deg C/min

*3: High purified type (for food packaging application)

Pellet Type

| Application | ||||||

|---|---|---|---|---|---|---|

| Type | Grade | MFR*1 (g/10min) | OTR*2 (cc 30mm/m2.day.atm) | Film | Injection | Spinning |

| Standard | BVE8049P*3 | 4.3 | Min99.0 | X | X | |

| High MFR | OKS-8077P*3 | 30 | Min99.0 | X | X | |

| Flexibility | OKS-8074P*3 | 3.5 | Min99.0 | X | X | |

| High Flexibility | OKS-8095P*3 | 2.5 | Min99.0 | X | X | |

| Easily Dissolving | OKS-8042P | 23 | 89.0 | X | X | |

| Heat Resistance | OKS-8211P | 25 | Min98.0 | X | ||

*1: Measured with Melt Indexer (210 deg C, 2160g) (200 deg C for OKS-8042P, 230 deg C for OKS-8211P

*2: Measured at 23 deg C / 65%RH

*3: High purified type (for food packaging application)

Oil & Gas Application Grades

Powder Type

| Type | Grade | Target Well Temperature (Degree F) |

|---|---|---|

| Standard | OKS-8139 | < 160 |

| High Soluble | OKS-1265 | < 120 |

| Ultra-high Soluble | OKS-1267 | < 70 |

Pellet Type

| Type | Grade | Target Well Temperature (Degree F) |

|---|---|---|

| Standard | OKS-8201P | < 160 |

| High Soluble | OKS-8196P | < 120 |

| Ultra-high Soluble | BVE8049P | < 70 |

G-Polymer Powder Type

The numbers above are sample values, not guaranteed values.

*1 : 4% aqueous solution at 20oC | *2 : Measured by DSC

Pellet Type

*1 : Measured by DSC

*2 : 2160 gm 210 oC (OKS-8042P:190oC)

*3 : 20oC 65%RH

The numbers above are sample values, not guaranteed values.

Properties

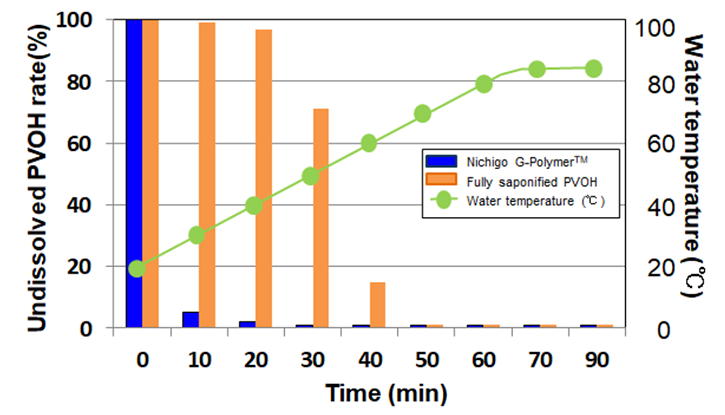

Water Solubility (Comparison with Conventional PVOH)

Nichigo G-Polymer™ shows excellent water solubility even at low temperature

[Test conditions]

After mixing Nichigo G-Polymer™ in agitated water and heating to dissolve it.

Temperature: Raise from 20 degree C to 85 degree C (1 degree C/min)

Concentration: 10%

| Solubility Temp/Time | |||

|---|---|---|---|

| Grade | 20°C/2hr | 70°C/1hr | 90°C/1hr |

| Nichigo G-Polymer™ AZF8035W | Disolve | Disolve | Disolve |

| Nichigo G-Polymer™ OKS-1011 | Partially Disolve | Disolve | Disolve |

| Fully saponified PVOH | Partially Disolve | Partially Disolve | Disolve |

[Test conditions]

After mixing Nichigo G-Polymer™ in agitated water and heating it to the

temperature that it dissolves, mixing for a fixed amount of time and cooling, check the state of dissolution.

Test concentration: 5%

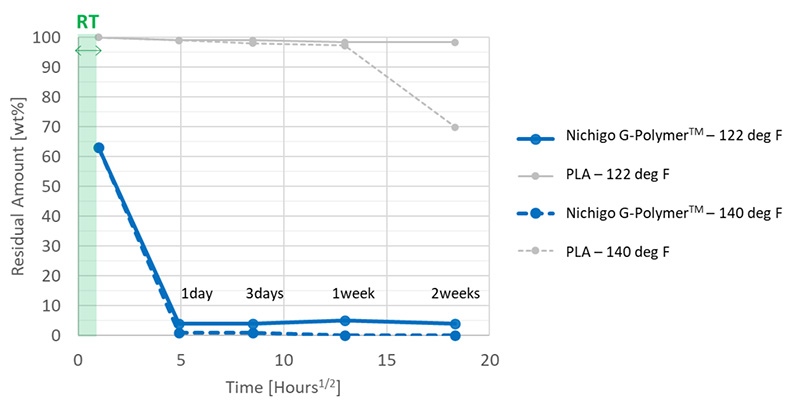

Water Solubility for Diverting Agent Application (Comparison with PLA)

Nichigo G-Polymer™ shows excellent water solubility even at low temperature.

[Test conditions]

Sample

* G-Polymer: Blend of powder and pellet

* PLA: Blend of powder and pellet

1g sample / 100g RT tap water

Plugging process: Stir at medium speed for 1 hour @ RT

Dissolution process: Hold at 122/140 degree F in dryer (1, 3days, 1, 2 weeks)

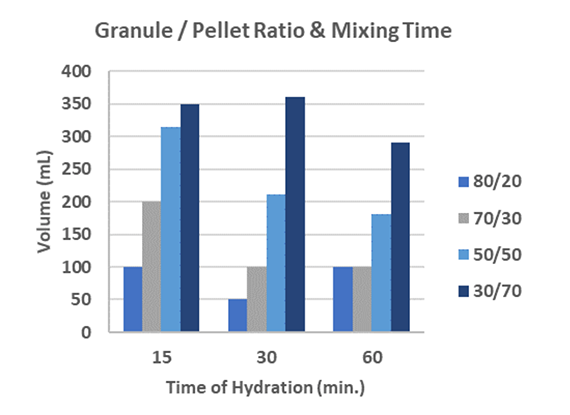

Bridging Mechanism of Nichigo G - Polymer™

Bridging Properties on Slit

Nichigo G-Polymer™ shows excellent bridging property on small slit.

[Test conditions]

Slot tester

60g polymer/5g guar/1L tap water were stirred at RT for 60 minutes

Slurry was injected into tester (slot size: 0.072/0.025 inch), then pressurized 200 psi

Measure effluent thru slot, less the better

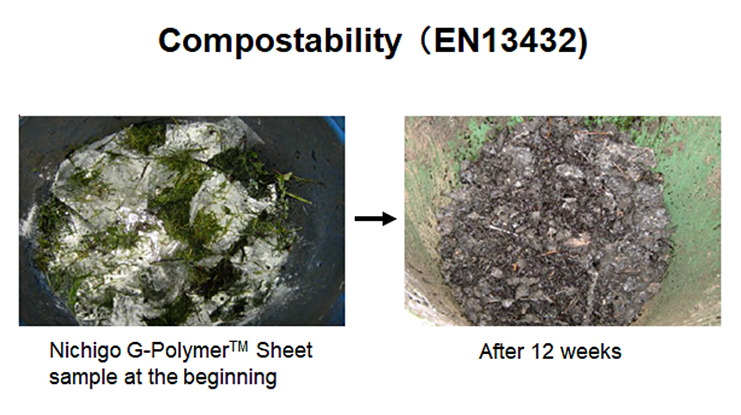

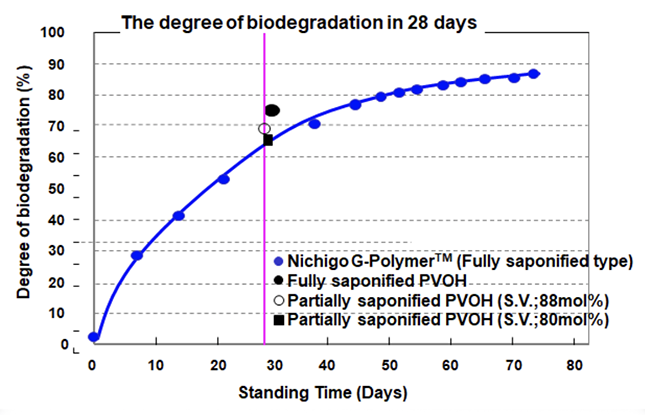

Compostability

Nichigo G-Polymer™ BVE8049P, OKS-8077P, OKS-8095P and BTR8002P are confirmed by US and EU standard (EN13432 and EN14851).

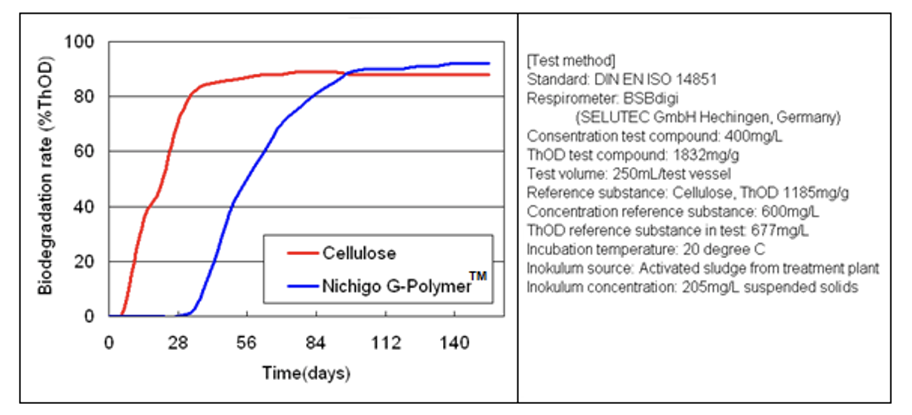

Biodegradability

[Test conditions]

Conducted based on the method described in JIS K6950.

Equipment: closed oxygen consumption measurement device

(Ohkura Electric Co., Ltd. OM3100A Coulometer)

Microorganism concentration and source: 90 mg/l return sludge from our company factory

Amount of sample added: 600μl

Standard testing culture fluid: 300 ml

Temperature: 25 ± 1 degree C

Test period: 70 days

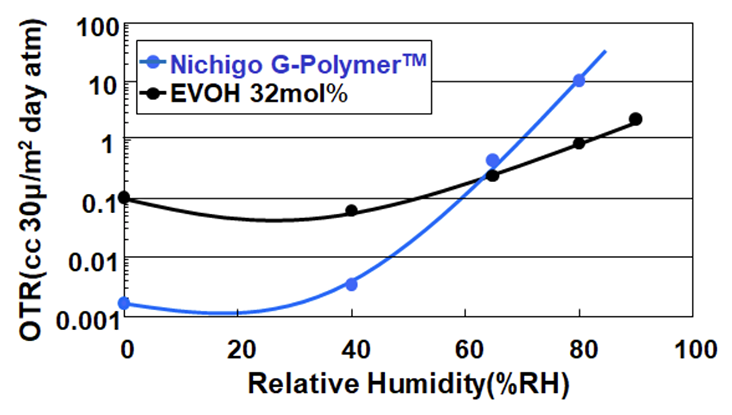

Oxygen Gas Barrier Performance

| OTR | |||

|---|---|---|---|

| Sample | cc 20μm/m2 day atm | Normalized with Nichigo G-Polymer™ | |

| Nichigo G-Polymer™ BVE8049Q | 0.0023 | 1 | |

| Fully saponified PVOH | 0.005 | 2 | |

| EVOH 29mol% | 0.07 | 30 | |

| EVOH 44mol% | 1.3 | 600 | |

| Nylon 6 | 76 | 35,000 | |

| Polypropylene | 3,900 | 1,700,000 | |

Sample : solution coating film (Single layer film is used for Nylon 6 and Polypropylene)

Measurement conditions: 20 degree C, dry

Nichigo G-Polymer™ shows excellent barrier performance under lower humidity conditions

Apparatus : OXTRAN2/20

Sample : PP/tie/Nichigo G-Polymer™ BVE8049P or EVOH/tie/PP multilayer film

Condition : 23 degree

Hydrogen Gas Barrier Performance

| Sample | cc 20μm/m2 day atm |

|---|---|

| Nichigo G-Polymer™ BVE8049Q | <3 |

| EVOH 29mol% | 26 |

| EVOH 44mol% | 440 |

| Nylon 6 | 900 |

| Nylon 11 | 5,600 |

Sample: single layer film

Measurement conditions: dry

Nichigo G-Polymer™, EVOH: 41 degree C

Nylon resin: room temperature

Carbon Dioxide Gas Barrier Performance

| Samples | cc 20μm/m2 day atm | Normalized with Nichigo G-Polymer™ |

|---|---|---|

| Nichigo G-Polymer™ BVE8049Q | 0.0058 | 1 |

| Fully saponified PVOH | 0.0068 | 1.2 |

| EVOH 32mol% | 1.3 | 224 |

Sample: biaxial stretched film

Measurement conditions: 20 degree C, dry

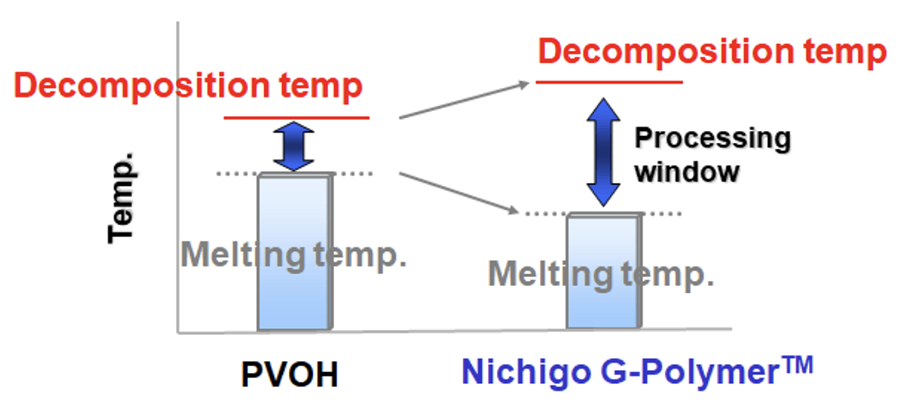

Nichigo G-Polymer™ is a resin that can be extruded.

Compared to PVOH, Nichigo G-Polymer™ has a low melting point and a high thermal decomposition temperature, giving it outstanding extrusion performance.

Applicable Extrusion Methods

| Application | ||||||

|---|---|---|---|---|---|---|

| Type | Grade | MFR (g/10min) |

OTR (cc 30mm/m 2.day.atm) |

Film | Injection | Spinning |

| Standard | BVE8049P*3 | 4.3 | Min99.0 | X | X | |

| High MFR | OKS-8077P*3 | 30 | Min99.0 | X | X | |

| Flexibility | OKS-8074P*3 | 3.5 | Min99.0 | X | X | |

| High Flexibility | OKS-8095P*3 | 2.5 | 93.0 | X | X | |

| Easily Dissolving | OKS-8042P | 23 | 89.0 | X | X | |

| Heat Resistance | OKS-8211P | 25 | Min98.0 | X | ||

*1 Measured with Melt Indexer (210 deg C, 2160g) (200 deg C for OKS-8042P, 230 deg C for OKS-8211P)

*2 Measured at 23 deg C / 65%RH

*3 High purified type (for food packaging application)

By small amounts added, Nichigo G-Polymer™ exhibits good dispersion with silica, alumina and other hydrophilic inorganic compounds.

By small amounts added, it even has good dispersion with colloidal silica, forming films with outstanding transparency and luster.

[Film producing conditions]Anionic colloidal silica/resin=90/10wt%

Disperse mixed anionic colloidal silica / resin solution with homogenizer (5,000 rpm for 5 min)

After coating PET film using a bar coater, dry at 105 degree C for 5 min

Processing & Handling

Storage

Since this is a fine powder, use rubber gloves, dust masks, protective eyewear and other protective gear when handling it in order to protect skin and eyes

When handling large amounts of it, install dust collection equipment. In addition, since there is a danger of dust explosions occurring from ignition caused by static electricity sparks, use grounding equipment and conductive dust filtration cloth and take other countermeasures.

Store in a place where it will not be dampened by rain, for example, because it could dissolve. Moreover, because it can easily harden into blocks if it absorbs moisture, avoid storing it in hot and humid conditions.

Dissolving

Add to room temperature water as you stir it and mix it thoroughly. Raise the temperature as you stir it to 80-90°C and dissolve it for 30-60 minutes

The formation of undissolved powder can result in unstable solution. In order to prevent the occurrence of undissolved lumps when adding the polymer, observe the following precautions.

- Use room-temperature water. (Do not use warm water.)

- Stir thoroughly as you add the polymer gradually.

Molding

We provide a casting grade of Nichigo G-Polymer™ that has water content of less than 0.5 wt%, in a moisture-resistant package, so there is no need to pre-dry it before casting.

Nichigo G-Polymer™ is an absorbent resin. If its package is left open for a long period of time, it could absorb moisture and this could result in foaming at the time of casting. Use heat-sealing to hermetically seal the package for storage.

We do not recommend redrying, because it could cause yellowing, F.E., etc.

To the greatest extent possible, avoid leaving Nichigo G-Polymer™ in processing equipment.

Doing so could result in foaming and gelification. When stopping processing, purge it with LDPE or LLDPE. Consider approximately 20 minutes to be the maximum amount of time that it should be left in equipment.