Properties

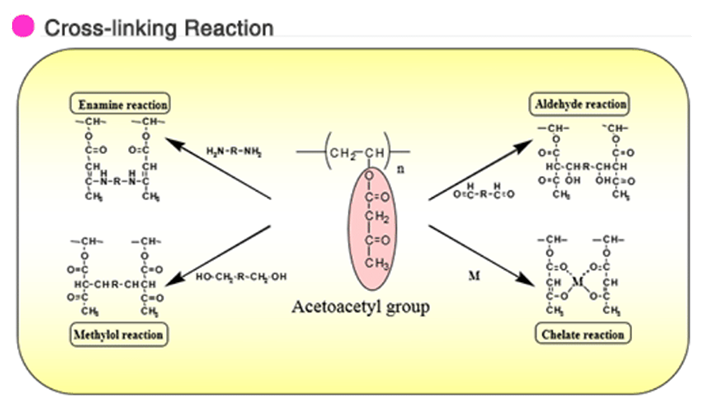

- Highly chemically reactive due to functional group

- Forms tough, transparent membranes from water solution.

- Adding specific waterproofing / cross-linking agents (such as glyoxal), followed by air drying and heat treatment, produces highly water- and hydrothermal-resistant films.

- Excellent water-resistant adhesion.

- Forms all types of metallic ions and chelate.

- Effective emulsifier or dispersant due to surface activity and protective colloid properties. In particular, it dramatically improves the water resistance of Polyvinyl Acetate emulsion.

- Excellent formaldehyde adsorbing properties.

Grades List

| Product Grade | Saponification Degree (mol) |

Viscosity*1 (mPa.s) | pH*2 | Volatile Matter (%) | Applications |

|---|---|---|---|---|---|

| Z-100 | Min 98.5 | 4.5-6.0 | 3.5-5.0 | Max 5.0 | Thermal recording paper |

| Z-200 | Min 99.0 | 11.5-14.0 | 3.5-5.0 | Max 5.0 | Thermal recording paper, Adhesives |

| Z-200H | Min 99.0 | 11.5-14.5 | – | Max 5.0 | Thermal recording paper |

| Z-205 | Min 99.0 | 11.5-14.0 | 3.5-5.0 | Max 5.0 | Thermal recording paper |

| Z-210 | 95.0-97.0 | 11.5-15.0 | 4.0-5.0 | Max 5.0 | Emulsifier for vinyl acetate |

| Z-220 | 90.5-92.5 | 11.5-15.0 | 4.0-5.0 | Max 5.0 | Emulsifier for vinyl acetate |

| Z-300 | 98.0-99.0 | 24.0-30.0 | 3.5-5.0 | Max 5.0 | Thermal recording paper, Adhesives |

| Z-320 | 92.0-94.0 | 19.0-24.0 | 3.5-5.0 | Max 5.0 | Water based polymer – isocyanate adhesive |

| Z-410 | 97.5-98.5 | 43.5-58.5 | 3.5-5.5 | Max 5.0 | Thermal recording paper |

*2: 4% aqueous solution

Applications

Coating Agent

The demand for GOHSENX™ Z is increasing for applications to coated and non-coated paper products requiring a higher degree of water resistance. As a coating agent for thermal printing paper and ink jet printing paper, GOHSENX™ Z has been extremely popular.

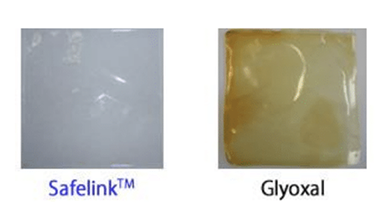

Recommended Cross-linker (Safelink™ SPM-01)

Safelink™ SPM-01 is a new cross-linking agent for GOHSENX™ Z developed by our own technique. Both type of powdered and 10% aqueous solution are available.

Characteristics

- Excellent cross-linkability for GOHSENX™ Z

- High safety with less toxicity compared to other cross-linking agent

- Easy handling with longer pot life after mixed with GOHSENX™ Z

- Excellent color stability against heat and aging conditions

| Cross-linking Agent | Amount (parts) | pH | Elution rate*1(%) | Pot life*2 | YI*3 |

|---|---|---|---|---|---|

| Safelink SPM-01 | 5 | 5.0 | 3 | More than 7 days | 4 |

| Glyoxal | 1 | 4.4 | 6 | 7 days | 12 |

*2: Period of reaching viscosity of 7% aqueous solution to twice at 23 degree C.

*3: After 100m film left for 7 days at 40 degree C, 90%RH. (NIPPON DENSHOKU &Sigma90)

Other Cross-linkers

| Cross-linker | Product name | Chemical name | Product company | Addition*1 | ph | Elution rate*2 (%) | Pot Life*3 (hr) |

|---|---|---|---|---|---|---|---|

| Amine | MXDA | Methaxylenediamin | MITSUBISHI GAS CHEMICAL COMPANY, INC. | 3 | 10.5 | 20 | 0.1 |

| 1,3-BAC | 1,3-bis (aminomethyl)cyclohexane | 3 | 10.5 | 20 | 0.1 | ||

| Hydrazide | ADH | Adipoyldihydrazide | Otsuka Chemical Co., Ltd. | 3 | 5.4 | 1001) | 0.1 |

| APA 280 | 3 | 5.4 | 15 | 0.1 | |||

| Aldehyde | SEQUAREZ 755 | Polyol Carbonyl Adduct | OMNOVA Solutions Inc. | 3 | 4.3 | 10 | 9 |

| Metal Salt | ZIRCOZOL ZC-2 | ZrO(OH)ClnH2O | DAIICHI KIGENSO KAGAKU KOGYO CO., LTD. | 3 | 1.9 | 3 | Min.168 |

| ZIRCOZOL AC-7 | (NH4)2ZrO(CO3)2 | 3 | 4.8 | 202) | Min.168 |

*2 : After soaking dry film pretreated 70 degree C x 5min in 80 degree C water for 1hr

*3 : Measure period until 10% aqueous solution viscosity would be twice than initial viscosity as 40 degree C

1) : insoluble in cold water

2) : Elution rate at 90 degree C

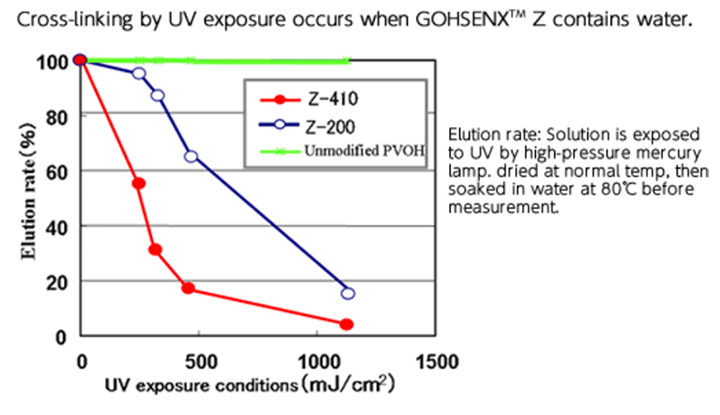

Cross-linking Property by UV Irradiation

Emulsifier

By using GOHSENX™ Z as an emulsion protective colloid agent for vinyl acetate-based emulsion, a unique emulsion will be obtained. This will have a higher degree of water-resistant bond strength, unachievable with standard PVOH products.

| Emulsion NO. | 1 | 2 | 3 | 4 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Polymerization Recipe |

Z-210(parts) Z-220(parts) N-300(parts) GM-14(parts) |

4 – – – |

– 3 – – |

– – 5 – |

– – – 3 |

|||||||||

| Vinyl acetate (parts) Water (parts) Polymerization initiator |

36 60 APS |

37 60 APS |

45 50 HPO/TA |

47 50 APS |

||||||||||

| Properties | Evaporation residue (%) Viscosity(mPas,25 degree C) pH Apparent graft ratio (%) Freeze-thaw stability (number of cycles) Water proof adhesion test |

40 15,600 4.3 76.1 5< 13hr |

40 27,300 4.2 76.1 5< 95hr |

50 13,000 4.5 – 0 x |

50 53,000 4.0 42.3 5< x |

|||||||||

|

||||||||||||||

| Mixing ratio | Emulsion properties | G.f( % ) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Viscosity (mPa.s) | S.V.I. | Solids (%) | |||||||||||

| Z-200: 4 parts | Initiator (APS): 0.08 parts | 12,000 | 0.5 | 40 | 73 | ||||||||

| VAC: 36 parts | Buffer (NaOAc): 0.02 parts | ||||||||||||

| Pure water: 60 parts | |||||||||||||

| Z-100: 5 parts | Initiator (APS): 0.08 parts | 2,300 | 0.3 | 50 | 69 | ||||||||

| VAC: 45 parts | Buffer (NaOAc): 0.02 parts | ||||||||||||

| Pure water: 50 parts | |||||||||||||

|

|||||||||||||

Adhesive and Binder

GOHSENX™ Z excels in adhesion to various materials with outstanding water resistance properties. We are currently expanding the scope of applications of GOHSENX™ Z products.

Dissolution and Storage

Dissolving GOHSENX™ Z

GOHSENX™ is charged into room temperature water while stirring. The water is heated immediately with constant stirring, and kept at 90 to 95 degree C for 30 to 60 minutes.

Storing GOHSENX™ Z

The properties of a GOHSENX™ Z aqueous solution may change (e.g. its viscosity may increase) if it is stored for long periods of time. Color changes or increased viscosity may also be induced by rust or metallic ions entering the solution.

Note

- When mixing with defoaming agents, anticorrosives, antiseptics or other chemicals, follow the directions given for handling these chemicals.

- Avoid storage in hot, humid areas as the product may incur blocking or its properties may change.

GOHSENX™ Z will maintain its properties and stability if stored at moderate temperatures. - However, its functional group makes it highly chemically reactive, and introducing other chemicals into the product may result in its becoming insoluble or saponified.

| Polymer | COD (mg/kg)x104 | BOD5 (mg/kg)x102 |

|---|---|---|

| GOHSENX™ Z | 99 | 70 |

| GOHSENOL™ | 60 ~ 100 | 50 ~ 100 |

| Corn Starch | 36 | 7,400 |

|

||