Properties

- Powerful dispersant of organic or inorganic materials. Suitable for dispersant of dye and developer for thermal recording paper.

- Excellent emulsifying power and protective colloid properties.

- In acrylic or styrene emulsion form, it is capable of stable emulsification polymerization unachievable with standard PVOH. The GOHSENX™-based emulsion boasts excellent stability and has various additional features.

Grades List

| Product Grade | Saponification Degree (mol%) | Viscosity*1 (mPa.s) | pH | Applications |

|---|---|---|---|---|

| L-3266 | 86.5-89.0 | 2.3-2.7 | 5.0-7.0 | Dispersant of dye and developer for thermal recording paper, Emulsifier for Acrylic-Em and PVAc-Em |

| CKS-50 | Min 99.0 | 2.5-3.0 | 5.0-6.5 |

*2: 4% aqueous solution

Applications

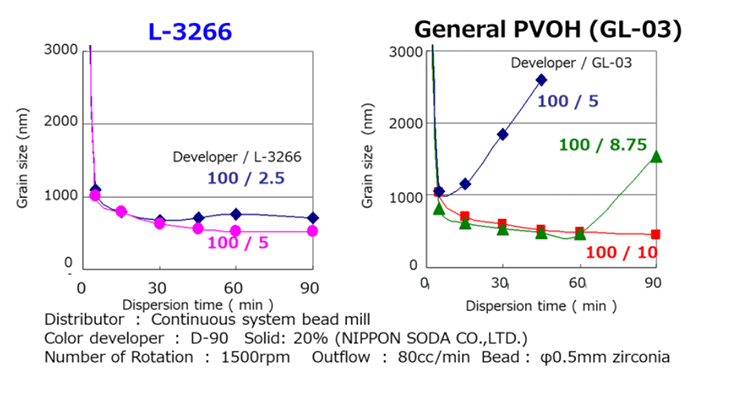

Dispersant of Dye and Developer for Thermal Recording Paper

GOHSENX™ L is well used for Dispersant of dye and developer for thermal recording paper thanks to following features.

- Easy to prepare fine particles in a short time

- Superior in stability of the dispersion

- To improve image of resolution and stability of the whiteness

- Superior in antifoaming property

Emulsifier for Acrylic Emulsion Synthesis

GOHSENX™ L enables the polymerization of acrylic emulsion which is not achieved by general PVOH. The achieved emulsion has good stability, high adhesive strength, excellent dry film performances.

| Monomer ratio (MMA/BA, wt%) | 55/45 (Tg: 11 degree C) | |

|---|---|---|

| Emulsifier (%/monomer) | GOHSENX™ L-3266 | |

| 7 | ||

| Emulsion properties | Solid Content (wt%) | 46 |

| Viscosity (mPa.s) 25 degree C, 60rpm | 1,100 | |

| Particle size (nm) | 120 | |

Method

- Emulsification polymerization

- Monomer concentration (%): 42

- Polymerization initiator (%/whole system): 5% Ammonium peroxodisulfate aq./10% t-butyl hydroperoxide aq.=1.8/0.4

- Duration of pre-emulsion dropping: 3 hours

- Polymerization temperature: 75 degree C

Dissolution Method

GOHSENX™ L is charged into room temperature water slowly in small amounts, and thoroughly dispersed. The water is heated, with constant stirring, the temperature is kept at 80 to 90 degree C for 30 to 60 minutes.