Solution coating film with Nichigo G-Polymer™

By coating substrate with a Nichigo G-Polymer™ aqueous solution, high gas barrier performance can be achieved.

Viscosity*1

4.5 mPa.s

OTR*2

4.5 cc * 3 μm / m2 *day*atm

Note

Standard type, Powder form

Viscosity*1

3.0 mPa.s

OTR*2

4.5 cc * 3 μm / m2 *day*atm

Note

Low viscosity type, Powder form

The numbers above are sample values, not guaranteed values.

*1: Viscosity of 4% aqueous solution at 20 deg C

*2: Measured at 23 deg C / 65%RH

*2: Measured at 23 deg C / 65%RH

Recommended coating conditions

- Solvent: water or water/alcohol (e.g. water/ethanol with ethanol 50wt% or less)

- Solution concentration: 5-15% (according to coating equipment, desired coat thickness and line speed)

- Drying temperature: 70-120 degree C

In order to assure adhesion, we recommend the use of substrate film that has undergone corona treatment.

In addition, use of an anchor coating agent is also effective to enhance wetting and adhesion.

Oxygen permeability

Nichigo G-Polymer™ BVE8049Q

23 degree C, PET/resin = 25/3μm

Recommended anchor coating agents

Recommended anchor coat agents

| Trade name | TITA Bond T-100 | DIC DRY AC-108 |

|---|---|---|

| Manufacturer | Nippon Soda CO, Ltd. | DIC Graphics Corporation |

| Main ingredients | Polyethylene-imine | Polyethylene-imine |

| Concentration | 11 wt% | 8 wt% |

| Solvent | Water | Methylalcohol |

| Recommended dilution | 1/29 | 1/29 |

| Dilution solution | Water / Ethylalcohol 17 / 83 | Water / Alcohol 34.6 / 65.5 |

Adhesive strength with anchor coat agents

| Layer structure of film | Delamination section | Bonding strength (N/15mm) |

|---|---|---|

| Corona treated O-PET / TITA Bond T-100 / Nichigo G-Polymer™ BVE8049Q | PET/AC | 0.86 |

| Untreated O-PET / TITA Bond T-100 / Nichigo G-Polymer™ BVE8049Q | PET/AC | 0.07 |

| Corona treated OPP / TITA Bond T-100 / Nichigo G-Polymer™ BVE8049Q | PP/AC | 0.94 |

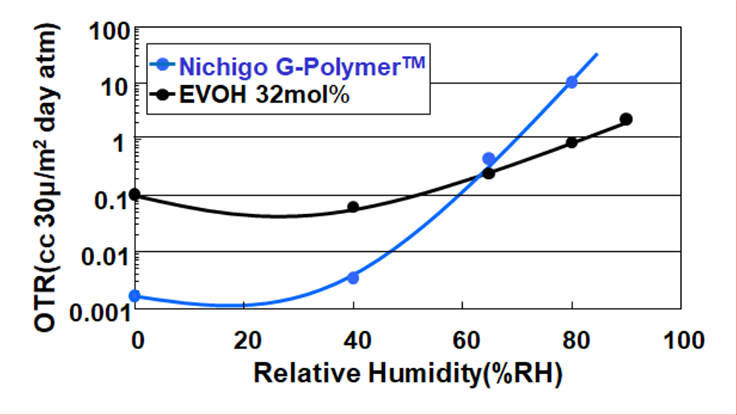

Improvement of Gas Barrier Property at High Humidity

Gas barrier properties are improved by adding layered inorganic additives.

| Sample | OTR(cc * 3 um / m2 *day*atm) | |

|---|---|---|

| 65%RH | 80%RH | |

| Nichigo G-Polymer™ OKS-8118 | 4-5 | 100-200 |

| OKS-8118 / Layered inorganic compound = 100/75 | 0.4 | 8-10 |

Layered inorganic additive : Kunipia F (Kunimine Kogyo)

Dry condition : 120 degree C x 10min