Compostable Gas Barrier Film with Nichigo G-Polymer™

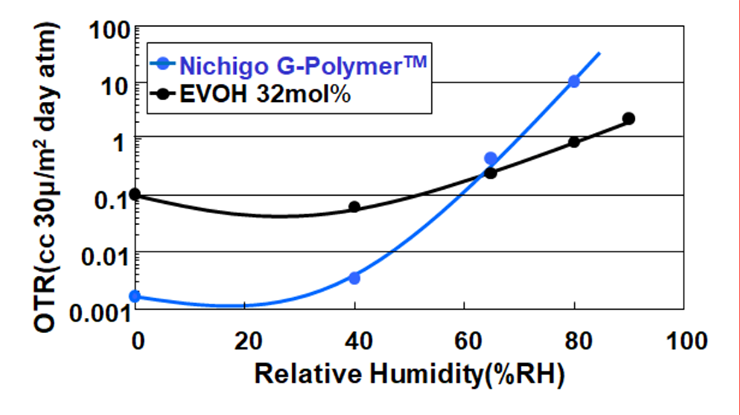

- In low humidity conditions, Nichigo G-Polymer™ has the highest gas barrier performance of any thermoplastic resin.

- In order to prevent loss of gas barrier performance in high humidity conditions, application of multiple layers is effective.

- COMPOSTABLE AND HIGH GAS BARRIER FILM; Fully biodegradable barrier package material can be made by combination of biodegradable resin such as Poly Lactic Acid(PLA) and Poly Butylene Succinate (PBS), biodegradable adhesion resin (BTR8002P: produced by Mitsubishi Chemical) and Nichigo G-Polymer™ as an intermediate barrier layer.

The numbers above are sample values, not guaranteed values.

*2: Measured with Melt Indexer (210 deg C, 2160g)

*3: Measured at 23 deg C / 65%RH

Oxygen permeability

Fully biodegradable film made by Nichigo G-Polymer™ shows excellent gas barrier performance.

Nichigo G-Polymer™ BVE8049P

| Layer (μm) | OTR (cc / tray day air) 23°C, inner 85%RH, outer 50%RH |

|---|---|

| PLA/BTR8002P/Nichigo G-Polymer™/BTR8002P/PLA 93 / 9 / 9 / 9 / 93 | 0.001 |

Nichigo G-Polymer™ exhibits excellent barrier performance in low humidity conditions.

Nichigo G-Polymer™ BVE8049P

Sample: multilayer film PP/tie/Nichigo G-Polymer™ (or EVOH)/tie/PP

Measurement conditions: 23 degree C

Film layer structure examples

[Co-extruded multilayer film (Fully biodegradable)]

PLA/tie(BTR8002P)/Nichigo G-Polymer™/tie(BTR8002P)/PLA

PBS/tie(BTR8002P)/Nichigo G-Polymer™/tie(BTR8002P)/PBS

[Co-extruded multilayer film]

PE/tie/Nichigo G-Polymer™/tie/PE

PP/tie/Nichigo G-Polymer™/tie/PP

Ny/tie/Nichigo G-Polymer™/tie/sealant

[Extrusion coated film]

O-PET/Nichigo G-Polymer™/tie/PE

[Paper coating]

Paper/Nichigo G-Polymer™/tie/PE

(When collected, the Nichigo G-Polymer™ layer is melted, and the paper and PE layers are easily detached)

Paper/PE/tie/Nichigo G-Polymer™/tie/PE