Injection molding with Nichigo G-Polymer™

- By injection molding with Nichigo G-Polymer™, water soluble cast items can be produced.

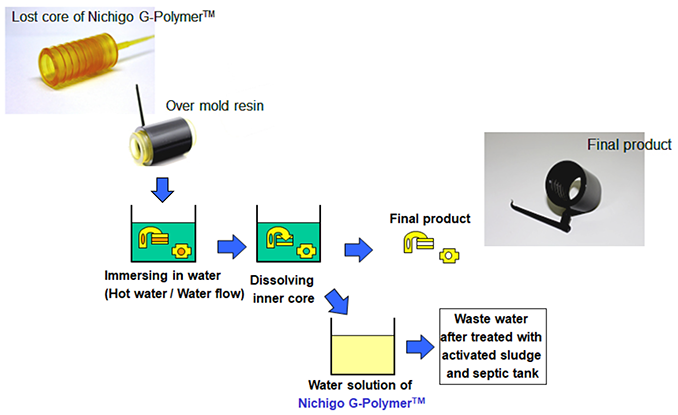

- Nichigo G-Polymer™ can be used for lost-core and outer-core material. Lost-core method is well known as producing curved and/or complicated tube structure plastic and set it melt and dissolve.

- It is possible to produce lost-core by Nichigo G-Polymer™, using ordinary injection molding and removal of lost-core can be easily done by warm water (cold water). So workers on site and machines are also in good circumstances because of no solvent.

- Further, it is possible to adjust solubility speed, resin strength, flowability, flexibility and softening temperature by controlling resin properties.

Grades

Melting Point*1

190 deg C

Tg*1

71 deg C

MFR*2

4.0 g/10min

Note

Standard type, Pellet form

Melting Point*1

185 deg C

Tg*1

71 deg C

MFR*2

3.5 g/10min

Note

Flexibility type, Pellet form

Melting Point*1

180 deg C

Tg*1

71 deg C

MFR*2

2.0 g/10min

Note

High flexibility type, Pellet form

Melting Point1

190 deg C

Tg*1

71 deg C

MFR*2

30 g/10min

Note

High MFR type, Pellet form

The numbers above are sample values, not guaranteed values.

*1: Measured with DSC, both heating and cooling speeds of 10 deg C/min

*2: Measured with Melt Indexer (210 deg C, 2160g)

*2: Measured with Melt Indexer (210 deg C, 2160g)

Lost Core and Outer Core Molding (Water Soluble)

Lost core and outer core made by Nichigo G-Polymer™ enable to produce one component product with complicated inside structure which needed to construct many parts.

Mechanical Properties of Nichigo G-Polymer™

| Properties | Test Method | Test Piece | TestCondition | Unit | Value | |

|---|---|---|---|---|---|---|

| MFR | ISO 1133 | 200-230°C | g/10min | 3-12 | ||

| Shrinking ratio | TD30-80°C | % | 0.045-0.310 | MD30-80°C | % | 0.057-0.321 |

| Tensile test | Breaking point | ISO 527 | Type A 200 x 10 x 4mm Dumbbell | Tensile speed 10mm/min | % | 2.5 | Breaking stress | N/mm2 | 88 | Tensile modulus | N/mm2 | 3,990 |

| Flexural test | Bending strength | ISO 178 | 80 x 10 x 4 mm | Flexural speed 2.0mm/min | Mpa | 191 |

| Bending modulus | Mpa | 7,150 | ||||

| Compression test | Compression strength | ISO 604 | 50 x 10 x 4 mm | Compression speed 1mm/min | Mpa | 5,180 |

| Izod impact | Not notched | ISO 180 | 64 x 10 x 4 mm | Load 11.8J | kJ/m2 | 18.3 |

| Notched | kJ/m2 | 2.7 | ||||

| Hardness | Rockwell hardness | ISO 2039-2 | 40 x 40 x 6 mm | Iron ball 6.35mm D Load 980.0N | HRM | 112 |

Data for Nichigo G-Polymer™ BVE8049P