Today, SoarnoL™ represents yet another revolution in preserving food flavor and freshness, offering innovative food-packaging technology that shuts out oxygen to prevent spoilage while maintaining the fragrance and flavor of the food. SoarnoL™ also has excellent transparency, helping to ensure that the food is beautifully presented.

SoarnoL™ exhibits excellent barrier properties not only for oxygen but for a variety of other gases. It also has excellent chemical and oil resistance that enable it to be used for a wide variety of other non-food applications, such as the plastic fuel tanks for automobiles, that have come to be used in recent years. Since SoarnoL™ is composed primarily of carbon, oxygen and hydrogen, it emits no toxic gases when burned, which has attracted a great deal of attention as an environmentally safe material.

What Is Soarnol?

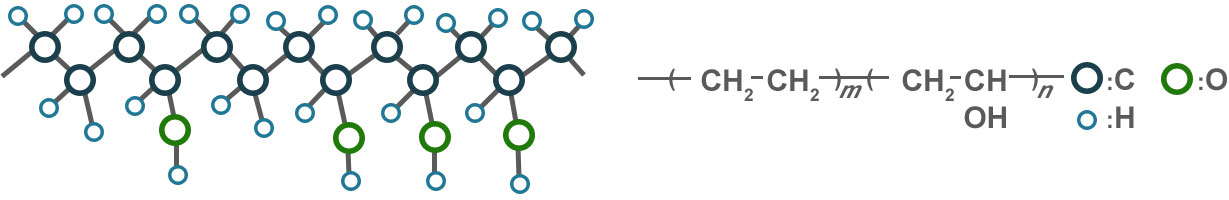

SoarnoL™ is the trade name of ethylene-vinyl alcohol copolymer (EVOH), developed by Mitsubishi Chemical through years of research.

SoarnoL™ combines the gas barrier properties, oil resistance, and transparency of polyvinyl alcohol (PVOH) with the water resistance, extrudability, and other properties of ethylene components.

Quality

SoarnoL™ is manufactured by Noltex L.L.C. in the state of Texas in the United States, the Mizushima Site in Okayama, Japan and Nippon Gohsei UK Ltd. Each manufacturing plant has been certified by the International Organization for Standardization (ISO) for the manufacture of SoarnoL™, and produces high quality resin that meets advancing and diversifying user needs.

Safety

In terms of molecular structure, SoarnoL™ is composed primarily of carbon, oxygen, and hydrogen, and when burned it emits primarily carbon dioxide and water vapor. It does not include harmful components that produce dioxins or other environmentally damaging substances. Furthermore, its combustion heat is only half that of polyethylene, helping to reduce the burden on incinerators and provide increased service life.

As a result of these features, SoarnoL™ can be looked upon as environmentally friendly.

0.010 cc.mil/100inch2.day.atm

0.010 cc.mil/100inch2.day.atm

0.015 cc.mil/100inch2.day.atm

0.015 cc.mil/100inch2.day.atm

0.036 cc.mil/100inch2.day.atm

0.036 cc.mil/100inch2.day.atm

0.076 cm3.20µm/m2.24hrs.MPa

0.076 cm3.20µm/m2.24hrs.MPa

The oxygen barrier properties of SoarnoL depend on ethylene content and humidity. The most suitable grade for a given purpose can be determined according to application and manufacturing process. Please contact us for suitable recommendations.

Properties

Processing

Information on processing technology of SoarnoL™ is shown in the following.

Regulatory

All SoarnoL™ grades do not contain heavy metals such as cadmium and lead, or any toxic substances.

SoarnoL™ standard grades comply with the following food law regulations:

U.S.A.

EU

and its amendments

Latin America

Japan

Its Latest Amendment No.18(Jan. 31, 1994)

Self-Restrictive Requirements on Food-Contacting Articles

Made of Polyolefins and Certain Polymers